The global materials industry is entering a decisive transition period where performance, sustainability, and regulatory compliance must coexist. Traditional petrochemical-based polymers, long valued for cost efficiency and durability, are now under scrutiny due to their carbon footprint and dependence on fossil feedstocks. In response, manufacturers across packaging,3D printing, and particularly textiles and fibers are accelerating the adoption of bio-based chemical building blocks.

Among the most promising platforms enabling this transformation are furan-based bio-chemicals, derived from renewable carbohydrates rather than crude oil. Renewable biomass serves as the foundational feedstock for next-generation materials. By leveraging a Smart Catalysis System, 5-hydroxymethylfurfural (HMF) is efficiently extracted and subsequently transformed via Short Process Technology. This method allows for the direct conversion of HMF into FDCA(Furandicarboxylic Acid), bypassing complex intermediate steps. The result is a streamlined production pathway that yields high-performance polymers capable of meeting rigorous industrial standards while significantly reducing carbon emissions.

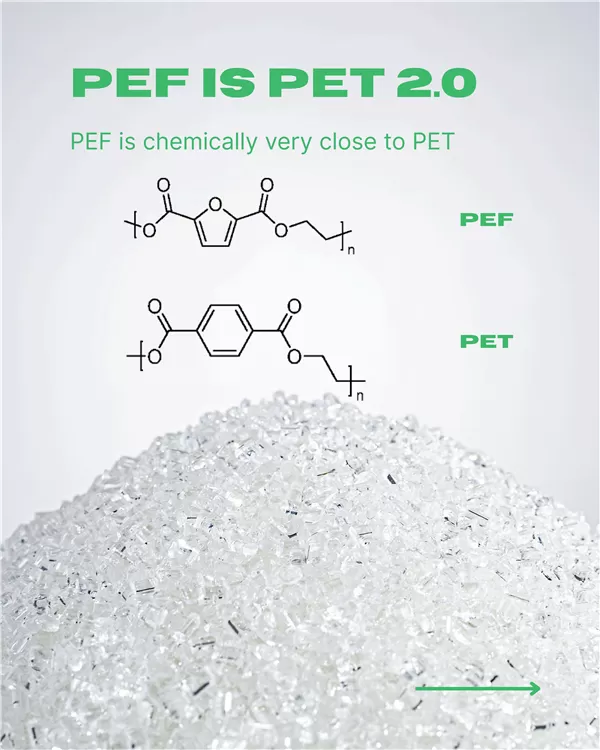

As the most in-demand furan monomer, FDCA provides a renewable alternative or complement to aromatic petrochemicals. lts key polymer, poly(ethylene 2,5-furandicarboxylate) (PEF), which is formed by polymerizing FDCA with ethylene glycol, delivers renewable carbon content without sacrificing material performance, and even delivers exceptional gas barrier properties for packaging, as well as antibacterial & mite-resistant, moisture-wicking, and UV-resistant features for fiber applications like sports fabrics, sustainable fabric materials.

As the textile industry seeks biobased alternatives to PET fibers and renewable polymer solutions, furan derivatives are moving from laboratory innovation to commercial-scale industrial relevance.

The shift toward renewable carbon is no longer a niche sustainability initiative — it is becoming a structural change in global materials sourcing. Petrochemical polymers face significant sustainability challenges, projected to drive one-third of global oil demand growth through 2030 and increase sector CO2 emissions by ~30% by 2050. Textile production, heavily dependent on petrochemical polymers such as PET, nylon, and acrylic, is responsible for a significant share of industrial greenhouse gas emissions. As a result, fiber producers are actively exploringbio-based polyester raw materialsthat can reduce lifecycle emissions while maintaining scalability.

Furan-based intermediates play a central role in this transition. HMF, produced from plant-derived sugars, serves as a renewable platform molecule that can be converted into high-value derivatives such as FDCA and DFF. FDCA, in particular, is recognized as a bio-based alternative to terephthalic acid (PTA), the petrochemical component used in conventional polyester production.

When FDCA replaces PTA in polymer synthesis, it enables the creation of PEF (polyethylene furanoate) and other FDCA-based polyesters, which offer improved barrier properties, strong mechanical performance, and a significantly lower fossil carbon footprint. These materials are increasingly viewed as viable feedstocks for renewable textile polymers and bio-based polyester fibers.

Beyond carbon reduction, renewable feedstocks also improve supply chain resilience. Dependence on agricultural or biomass-derived resources diversifies sourcing away from volatile fossil markets, supporting long-term stability for textile manufacturers seeking sustainable fiber raw materials.

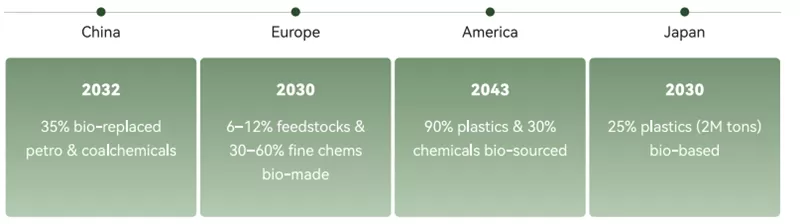

The transition from petroleum-based PET to bio-based PEF (Polyethylene Furanoate) is no longer just a technological ambition—it is being accelerated by a global "green arms race" in regulatory policy. For industry players, the motivation has shifted from voluntary corporate social responsibility (CSR) to mandatory compliance.

With the rapid development of the global green economy, bio-based materials have become a key driver ofindustrial transformation. Major countries are rolling out impactful policies to fast-track the substitution offossil-based materials.

Regulation is only part of the equation. Global consumer brands — especially in apparel, sportswear, and lifestyle sectors — are now major drivers of material innovation. Companies are setting science-based targets to reduce Scope 3 emissions and are scrutinizing the environmental footprint of every component in their supply chains, including fibers and textiles.

However, brand expectations go beyond sustainability claims. Materials must also deliver functional performance suitable for demanding applications such as activewear, outdoor gear, automotive textiles, and technical fabrics. This is where furan-based polymers present a compelling proposition.

FDCA-derived polyesters and related bio-based polymers, PEF can be engineered into high-strength, durable fibers suitable for performance textiles.

For brands seeking PET alternative fibers that combine sustainability with reliability, these materials support a transition toward low-carbon textile supply chains without compromising product quality or consumer expectations.

Beyond sustainability credentials, the chemical structure of furan-based monomers introduces unique performance advantages that are particularly relevant for fibers.

FDCA contributes to polyesters with improved rigidity and thermal properties, supporting the production of durable bio-based polyester fibers. In addition, furan rings can enhance barrier performance and dimensional stability, characteristics valuable in both textile and composite fiber applications.

Together, these building blocks demonstrate that furan chemistry is not limited to commodity sustainability — it is a platform for next-generation functional fiber materials.

As the global materials landscape evolves, the industrial adoption of furan-based bio-chemicals is transitioning from a niche trend to a strategic necessity. By offering scalable sustainable PET alternatives, GS Biomats empowers manufacturers to decouple from fossil feedstocks without compromising on durability or functionality. Our proprietary Smart Catalysis System and Short Process Technology ensure the efficient, high-purity production of bio-based FDCA and PEF polymers, which are critical for unlocking the next generation of bio-based polyester fibers and high-barrier packaging. Ultimately, partnering with a forward-looking FDCA manufacturer allows brands to not only secure a resilient supply of renewable carbon materials but also to decisively meet their Scope 3 emissions reduction targets in an increasingly regulated market.