The global packaging industry is under increasing pressure to reduce its reliance on fossil-based plastics while maintaining performance, safety, and cost efficiency. PET (polyethylene terephthalate) has long been the dominant material for beverage bottles, food containers, and cosmetic packaging due to its strength, clarity, and processability. However, growing regulatory demands, carbon reduction targets, and brand sustainability commitments are driving the search for PET alternative materials.

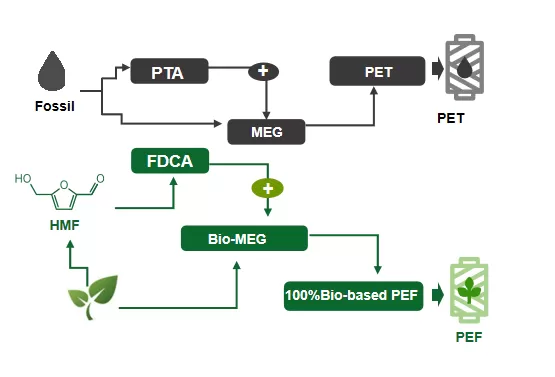

One of the most promising solutions is PEF (polyethylene furanoate) — a next-generation polyester derived from FDCA (Furandicarboxylic Acid), a bio-based building block produced from renewable carbohydrates. By replacing petroleum-based PTA (terephthalic acid) with FDCA, PEF introduces a new class of bio-based packaging materials that combine sustainability with superior performance.

As brand owners, packaging converters, and resin producers explore renewable packaging polymers, the FDCA-to-PEF value chain is rapidly gaining recognition as a key enabler of the transition toward sustainable packaging solutions.

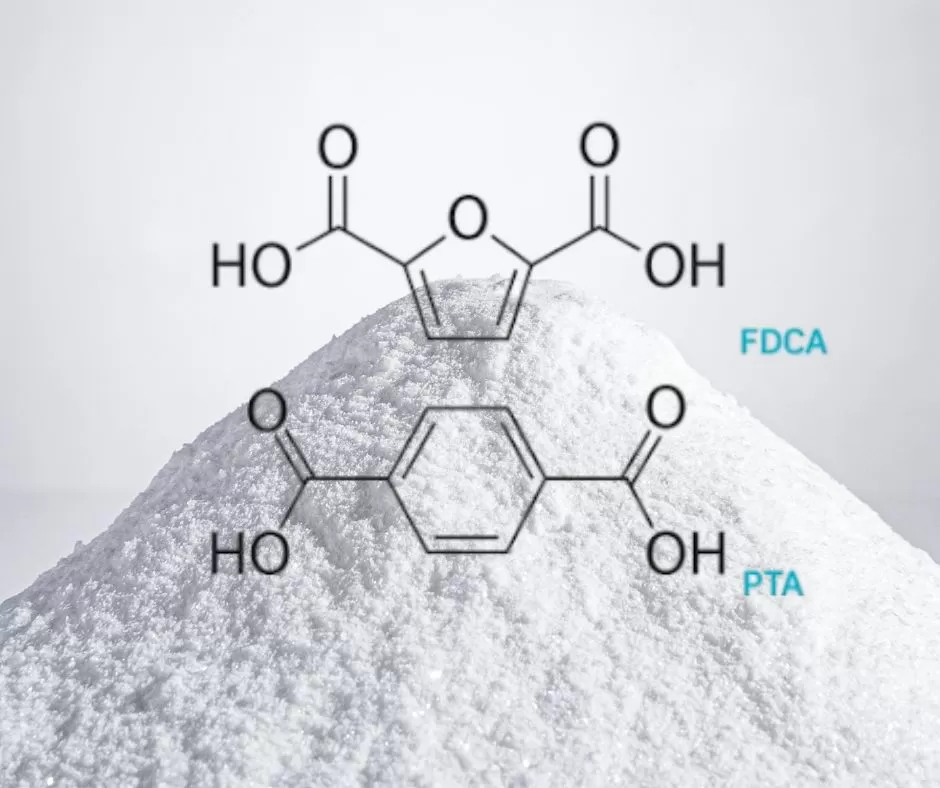

At the molecular level, the transformation from PET to PEF begins with the replacement of PTA (purified terephthalic acid) by FDCA, a bio-based diacid derived from HMF (5-hydroxymethylfurfural). While PTA is petroleum-derived and based on a benzene ring structure, FDCA features a furan ring, which contains an oxygen atom within a five-membered aromatic structure.

This structural difference may appear subtle, but it leads to meaningful changes in polymer behavior. The furan ring in FDCA creates stronger intermolecular interactions within the polymer chain compared with the benzene ring in PTA. As a result, PEF exhibits enhanced barrier properties, higher rigidity, and improved thermal performance relative to PET, also can be recycled independently or co-processed with PET, enabling a circular packaging lifecycle.

In addition, FDCA is produced from renewable carbon sources, such as plant-based sugars, allowing PEF to be classified as a bio-based polyester. This shift from fossil carbon to renewable carbon is fundamental to reducing the environmental footprint of packaging materials without altering established polyester processing technologies.

For packaging manufacturers, the ability to produce PEF using equipment similar to PET processing lines lowers the barrier to adoption and supports industrial scalability.

In the global packaging market, barrier protection isn't just a technical spec—it’s a guardian of brand reputation and product integrity. While PET has long been the industry standard, PEF (Polyethylene Furanoate) represents a quantum leap in material science, offering a "step-change" in gas transition limits.

The Science of Superior Protection

The unique furan-based molecular structure of PEF creates a tighter, more rigid polymer matrix. By significantly reducing molecular mobility, PEF acts as a high-density shield against gas diffusion.

Quantifying the Advantage: PEF vs. PET

When compared to conventional PET, PEF delivers a drastic improvement in barrier performance:

7× Higher Oxygen (O2) Barrier: Drastically slows oxidation, preserving the nutritional value and color of juices, dairy alternatives, and sauces.

15×–20× Higher Carbon Dioxide (CO2) Barrier: Maintains peak fizziness in carbonated beverages for significantly longer durations.

Enhanced Aroma Retention: Locks in complex flavor profiles, ensuring the consumer experiences the product exactly as intended.

Barrier performance directly contributes to one of the most valuable outcomes in packaging: extended product shelf life. In global supply chains where products travel long distances and remain on shelves for extended periods, packaging must provide consistent protection against environmental exposure.

PEF-based packaging can extend shelf life by slowing oxidation and gas exchange. This is especially important for:

Natural and preservative-free beverages

Sensitive food products with high oxygen reactivity

Premium products where flavor integrity is critical

By extending shelf life, PEF packaging can also help reduce food waste — an increasingly important sustainability metric for retailers and consumer brands. Lower product spoilage translates into reduced resource waste across the entire supply chain, from agricultural inputs to transportation and storage.

Thus, PEF supports not only carbon footprint reduction in packaging materials but also broader sustainability goals linked to food system efficiency.

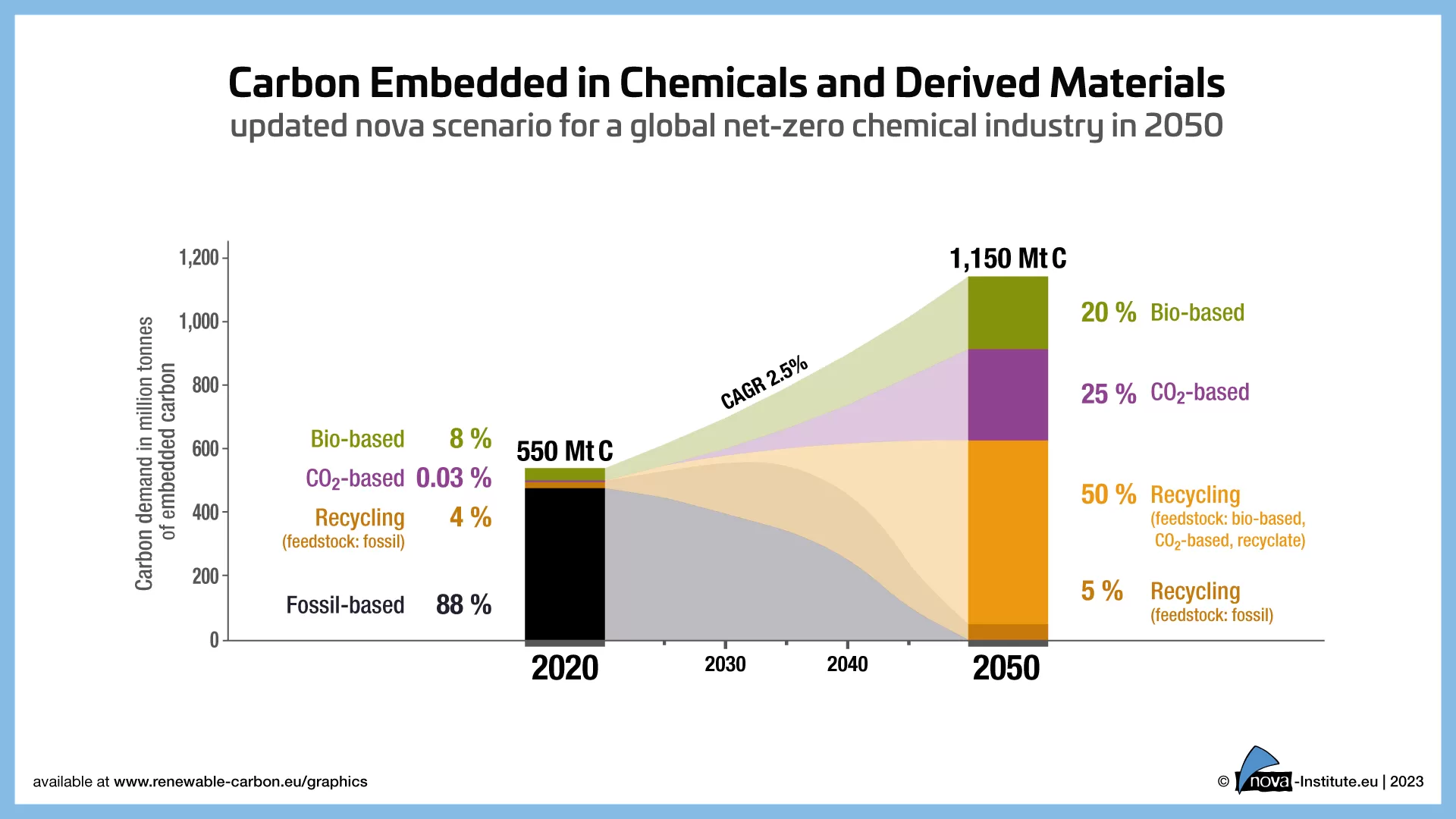

Beyond performance, one of the strongest drivers for adopting FDCA and Bio-based Polymers is the potential for significant carbon footprint reduction compared with petroleum-based plastics. Because FDCA is derived from plant-based feedstocks, the carbon embedded in PEF originates from atmospheric CO₂ captured during biomass growth, rather than from fossil carbon reserves.

Lifecycle assessments indicate that bio-based PEF can offer substantially lower greenhouse gas emissions than conventional PET, depending on feedstock sourcing and production efficiency. This makes PEF an important material option for companies working to meet:

Science-based emissions targets

Scope 3 carbon reduction goals

Circular economy and decarbonization commitments

Moreover, PEF is designed to be recyclable within polyester recycling streams, supporting the development of circular packaging systems. As infrastructure evolves, the combination of bio-based origin and recyclability positions PEF as a key material in the shift toward 100% recyclable bio-plastics.

For regulators and policymakers in Europe, the United States, Japan, and Korea — all key markets for sustainable packaging — materials like PEF align closely with long-term decarbonization and circular economy strategies.

The transition from PET to PEF is particularly relevant for brand owners seeking packaging that communicates both sustainability and premium quality. Because PEF retains the transparency and strength associated with PET while offering enhanced performance, it is well suited to high-value applications.

Carbonated drinks, juices, functional beverages, and plant-based drinks all benefit from improved gas barrier performance. PEF bottles can help brands maintain product freshness while showcasing a commitment to renewable packaging materials.

Oxygen-sensitive formulations such as serums, lotions, and fragrances require packaging that preserves active ingredients. The superior barrier properties of PEF support longer product stability while enabling brands to adopt bio-based packaging solutions that align with clean beauty and sustainability narratives.

Luxury food products, nutraceuticals, and specialty beverages often rely on packaging as part of their brand identity. Using FDCA-based PEF packaging allows these brands to differentiate through advanced material innovation and lower environmental impact.

Across these sectors, PEF offers a compelling combination of performance, sustainability, and brand storytelling, helping companies move beyond incremental improvements toward truly next-generation plastic alternatives.