The Fourth International Summit for Closed-loop Recycling of PET was grandly opened on February 19-20, 2025 in Hangzhou, China. The conference brings together raw material suppliers, end brands, recycling companies and technology providers in the global PET industry chain to discuss the future of the industry in terms of sustainable development and closed-loop recycling.

GS Biomats appeared at the summit with high-performance furan bio-based products and innovative recycling solutions. Dr. Wang Lei, Chairman of the Board of Directors of GS Biomats, gave an in-depth analysis of the key role of Furan Dicarboxylic Acid (FDCA) in enhancing the performance of sustainable packaging and optimizing the quality of rPET (Recycled PET) under the title of “FDCA - The Engine for Upgrading the Performance of rPET from the Innovation of Bio-Based Polyester”, and shared relevant technological breakthroughs and industrial development. He also shared the related technological breakthroughs and industrialization practices.

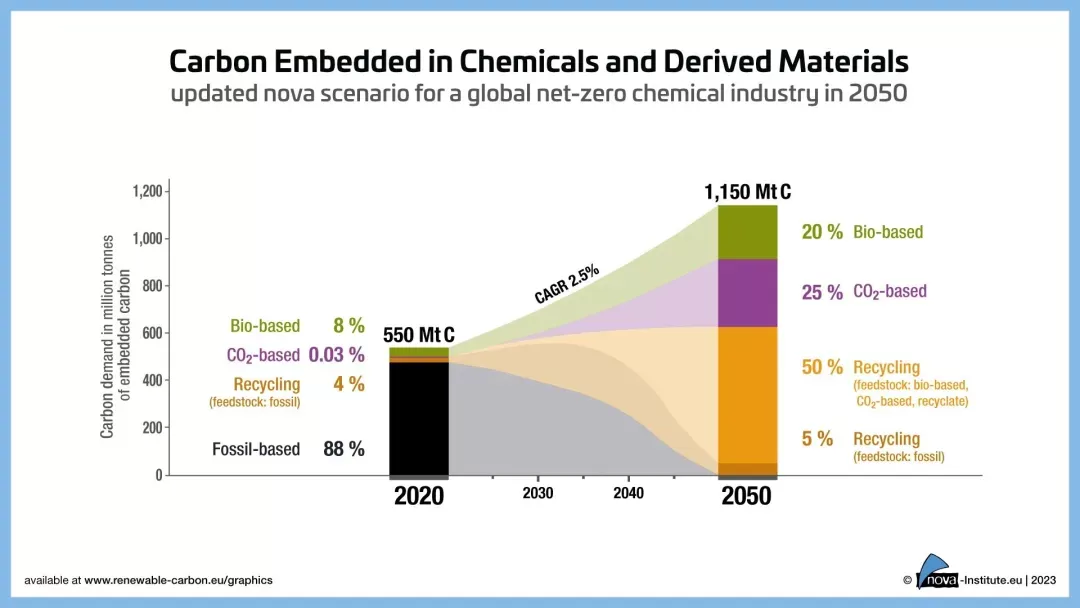

Driven by carbon neutrality targets, the global chemical industry's share of recovered carbon will rise to 55% by 2050, with 50% coming from renewable feedstocks (including biobased, CO₂-based, and recycled materials), according to projections by the Nova Institute, a global biotechnology research organization.

▲Carbon embedded in chemicals and derived materials

Against this backdrop of change, countries have introduced restrictive regulations to increase the requirements for the percentage of renewable and recyclable materials in packaging, pushing the industry to upgrade to a green and low-carbon direction. Bio-based material FDCA, with its unique furan ring oxygen-containing structure and excellent barrier performance and other advantages, has become a key breakthrough in bio-based polyester innovation, providing a new material choice for packaging, fiber and other fields, while it can enhance the recycling performance of the material.

One of the core challenges faced by the PET recycling industry is the material's performance decay during multiple recycling processes, including loss of clarity, reduced mechanical properties, etc. The FDCA-based polyester, PEF (polyfurylene dicarboxylate ethylene glycol), is structurally similar to PET. Studies have shown that adding up to 10% PEF to rPET can effectively improve the fogging phenomenon of recycled PET, while improving key indicators such as barrier and heat resistance. In addition, PEF can be co-cycled with PET.

▲ rPET within 10% PEF addition, can effectively improve the rPET injection molding process fogging phenomenon

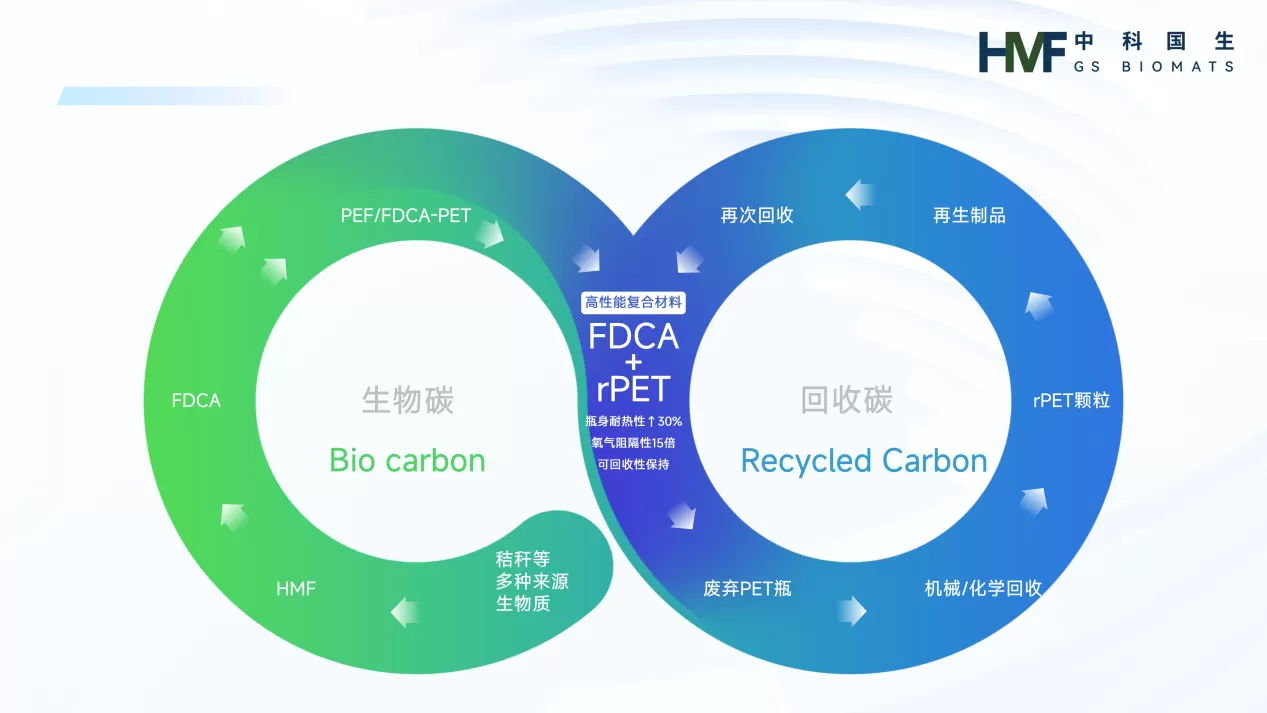

Currently, the EU and North American markets have recognized that PEF can be recycled with PET in single and multi-layer PET bottles with a 10% addition rate. Therefore, PEF is not only an ideal bio-based alternative to PET due to its excellent barrier properties and heat resistance, but also can be used in rPET system to improve its performance. rPET empowered by FDCA will become an important piece of the puzzle in the plastic recycling circular economy.

▲ FDCA Bio-Carbon and rPET Recycled Carbon Dual Cycle Model

As a pioneer in the global furan bio-based materials industry, GS Biomats has always been committed to providing the global market with material solutions that combine high performance and sustainability, and helping customers to realize economic benefits while reducing environmental impact. The company has now reached an annual production capacity of 400 tons of FDCA, with 10,000 tons of production capacity under construction, realizing the application verification and landing of furan biobased material FDCA in polyester packaging and fibers, special fire-resistant fibers and adhesives and other fields.

▲High purity quality FDCA

In 2025, the company will further promote the construction of 10,000-ton capacity and improve the international certification system, with more cost-competitive high-quality biobased materials, to help upstream and downstream industry chain partners to develop more innovative and environmentally friendly application scenarios, and jointly promote the development of global circular economy.