On December 2-3, 2025, GS Biomats, as a significant global entity in the field of furan-based bio-materials, was invited to attend the European Bioplastics Conference (EBC 25) and gave a keynote speech. During the conference, the company showcased its latest research and application advancements in the FDCA and PEF bio-polyester systems.

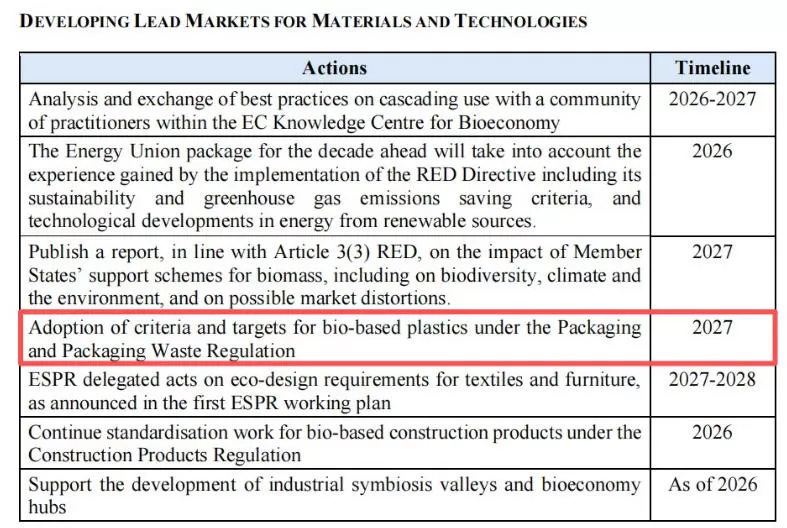

On the eve of the EBC conference, the European Commission released the EU Bioeconomy Strategy Framework for Competitiveness and Sustainability, explicitly incorporating bio-based plastics into the harmonized PPWR (Packaging and Packaging Waste Regulation) framework, and setting out plans to establish standards and mandatory targets for bio-based plastics by 2027.

This policy upgrade marks the formal integration of bio-based materials into Europe's long-term industrial system, providing innovative polyesters with clearer definitions, more unified standards, and more transparent market expectations.

▲ Bio-Based Plastics Incorporated into the EU PPWR Framework

For furan-based polyesters with PEF at their core, this integration delivers "dual visibility" across both regulatory and market dimensions. In particular, packaging applications are expected to benefit from a more predictable and clearly defined commercialization window.

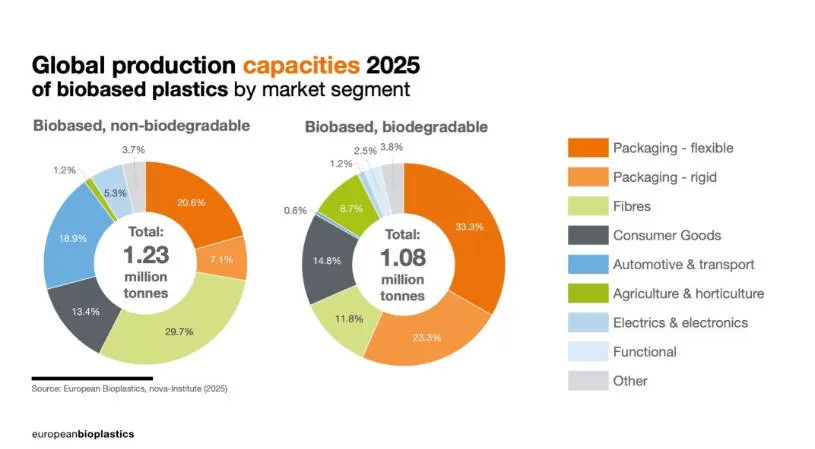

▲ Global Bio-Based Plastics Capacity by Market Segment, 2025

Furan-based bio-polyester, PEF is a high-performance material derived from 100% biomass and is fully compatible with existing PET recycling streams.

Its oxygen-containing furan ring structure endows the material with excellent chemical stability and functional performance, enabling intrinsically low-carbon and more efficient material pathways across key applications such as packaging and fibers. As energy systems, regulatory frameworks, and recycling infrastructures evolve in parallel, the "intrinsic high performance × sustainability" embodied by PEF is emerging as a critical inflection point in the upgrading of polyester materials.

Over the past year, GS Biomats has continued to deepen its layout around the practical application of PEF. Upstream, the company has steadily enhanced the industrial-scale production capability, quality consistency, and cost competitiveness of FDCA. At the materials level, it has accelerated the validation and scale-up of PEF across multiple application pathways.

High-Transparency Packaging

It enables the combination of high optical performance and high barrier properties for consumer products such as personal care and food, meeting brands' emerging requirements for "high performance × recyclability."

High-Barrier Packaging

It offers excellent gas barrier performance, meeting the stringent barrier and lightweighting requirements of applications such as carbonated beverages and beer.

Bio-based Blended Fibers

GS Biomats is collaborating with value-chain partners to develop blended fibers such as PEF × wool, PEF × TENCEL™, and PEF × silk, delivering high-performance textile solutions with more natural functionality as well as enhanced abrasion resistance and durability.

PEF's application development is moving beyond "laboratory validation" toward the parallel realization of process feasibility and commercial compatibility, providing the industry with new material options that are verifiable and scalable for mass production.

As a key global platform for collaboration, EBC offers an expanded forum for dialogue on the future of the bio-based industry worldwide. This year, GS Biomats engaged in in-depth discussions with multiple multinational brands and research institutions on the industrial positioning of furan-based polyesters, integration with recycling systems, future product development pathways, and routes toward standardization.

To support global cooperation, GS Biomats has completed the full registration of FDCA under the EU REACH regulation and is continuously advancing more certifications and compliance processes for PEF and related materials, providing a stable and credible supply foundation for international customers.

In the future, GS Biomats will continue to work with global industry chain partners to promote the construction of a next-generation bio-based polyester ecosystem, accelerating the material system towards lower carbon, higher performance, and greater sustainability.

About GS Biomats

GS Biomats is a pioneer in bio-based material manufacturing, specializing in the innovation and industrialization of furan-based chemicals. Leveraging self-developed continuous flow processes and “Short process” solutions, GS Biomats has achieved industrial-scale production of key bio-based compounds including 5-hydroxymethylfurfural (HMF) and furandicarboxylic acid (FDCA).

These new materials have been successfully commercialized in packaging, fibers, and aramid sectors. Guided by the mission to "Biomass change lives," GS Biomats aims to deliver high-performance, multifunctional, and sustainable furan-based materials for global clients