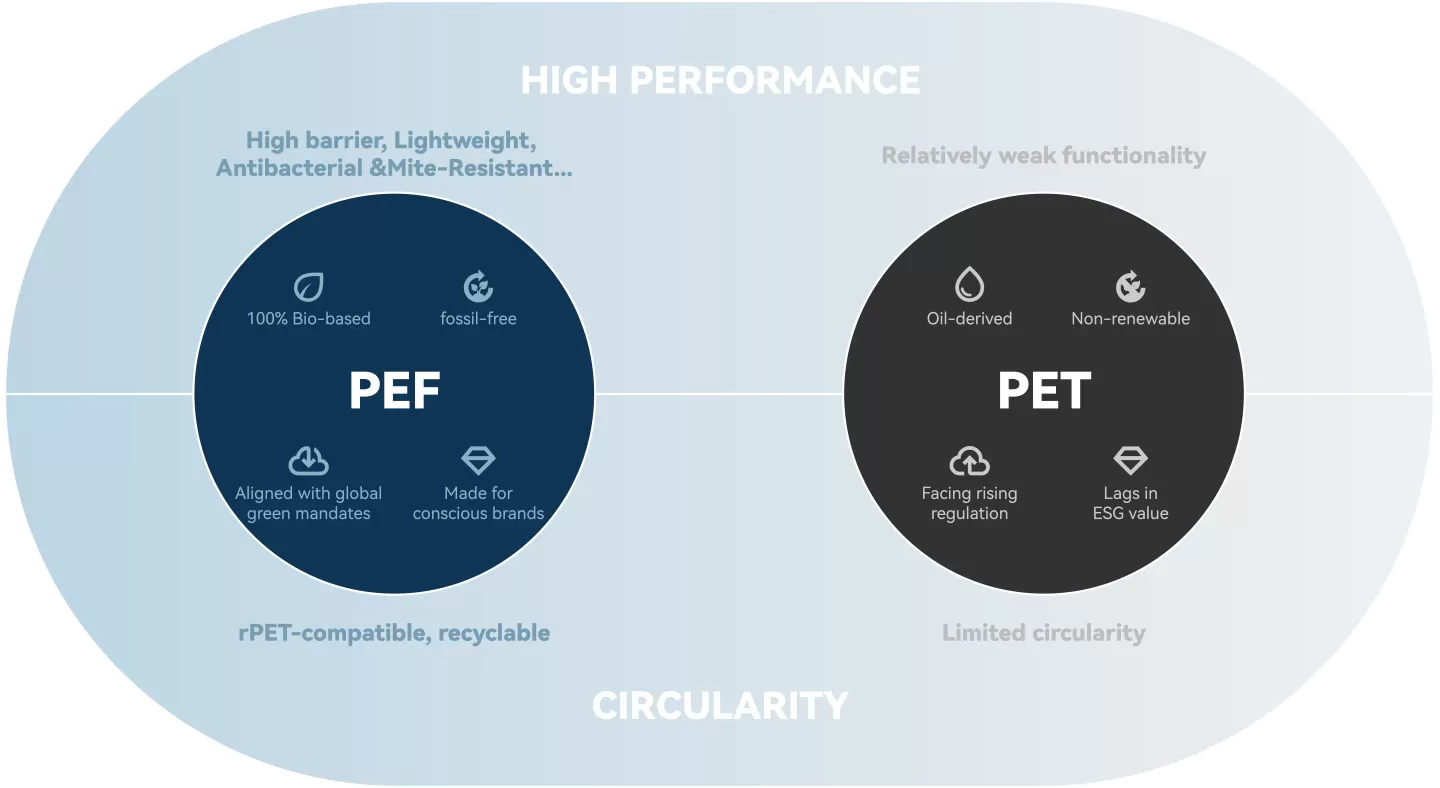

Why PEF outperforms traditional PET in sustainability and performance. Poly(ethylene 2,5-furandicarboxylate) (PEF) exhibits a higher glass transition temperature than PET, resulting in slower crystallization and easy processing. This high-performance, multifunctional polymer is process-compatible, recyclable, and renewable, enabling efficient integration with PET in packaging applications and enhancing fiber performance with natural antibacterial, mite-resistant, moisture-wicking, and UV-protective properties.

100% Bio-based Feedstock

Made from renewable biomass such as corn, straw, and agricultural residues, PEF offers a sustainable alternative to fossil-based PET. Sourced from 100% renewable biomass, PEF is a sustainable polymer that reduces carbon emissions by approximately 43.8% compared with PET, cutting reliance on fossil feedstocks while delivering full bio‑derived polymer credentials.

Lower Carbon Footprint

PEF reduces carbon emissions by approximately 43.8% compared with traditional PET, contributing to a lower environmental impact across its lifecycle.

Performance Upgrade

The unique oxygen-rich furan ring in PEF’s molecular backbone delivers inherent performance advantages on top of its green origin.

Recyclable in PET Stream

PEF can be recycled within existing PET streams and processed on the same production lines.

Multi-Functional Adaptability Across Applications

PEF exhibits tailored functionality across diverse applications—from packaging to fibers and 3D materials.

Modification & Process Compatibility

≤10% PEF improves rPET’s barrier, transparency, and heat resistance, while blending easily with diverse fibers to elevate textile performance.

Outstanding Mechanical Performance

Combining excellent toughness with high tensile strength, PEF outperforms PET in low‑temperature resistance and provides superior chemical stability and fatigue resistance, demonstrating the versatility of Bio-based Polyesters.