Soft to the touch, breathable comfort

Structured drape, wrinkle resistance

Applications:

sportswear

loungewear

casualwear

childrenswear

bedding

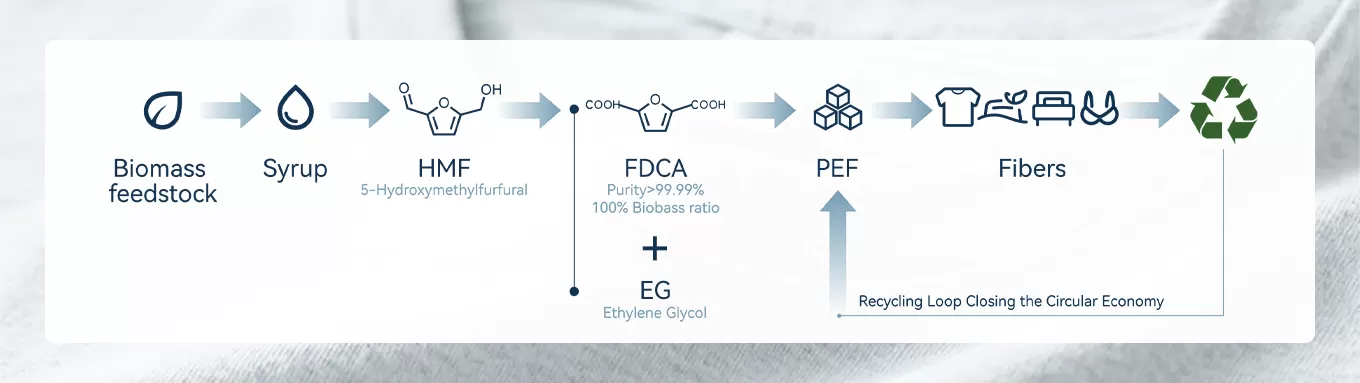

PEF fiber is a next-generation, bio-based polyester fiber derived from FDCA, designed for apparel, technical textiles, interior fabrics, flooring and automotive uses — enhancing comfort, durability and functional performance while opening new design possibilities. As a sustainable textile, Furan Biobased fibers (notably PEF-derived fibers) are available as filaments, staple fibers and more, and blend seamlessly with natural fibers like cotton, wool and lyocell as well as common synthetics.

Property | Furan bio-based fibers | PTT | PET | PBT | PA6 |

Strength/cN/dtex | 3-4 | 2.0-3.0 | 3.6-4.2 | 2.5-3.5 | 3.0-4.0 |

Boiling Water Shrinkage | 8-10% | 5%-10% | 3%-7% | 3%-10% | 3%-7% |

Density/(g·cm3) | 1.38-1.4 | 1.33 | 1.40 | 1.32 | 1.13 |

Melting Point/°C | 205-215 | 228 | 250-260 | 226 | 220 |

Glass Transition Temperature/°C | 86-90 | 45-60 | 80 | 30-45 | 40-60 |

Dye Type | Disperse/Cationic | Disperse | Disperse | Disperse | Acid |

Dyeing Temperature/°C | 100 | 100 | 130 | 100 | 100 |

Soft to the touch, breathable comfort

Structured drape, wrinkle resistance

Applications:

sportswear

loungewear

casualwear

childrenswear

bedding

Soft to the touch, wrinkle resistant

Naturally antibacterial, breathable comfort

Rich, long-lasting color performance

Applications:

suits

knitwear

sweaters

outdoor apparel

Silky drape, smooth to the touch

Moisture-wicking, wrinkle resistance

Naturally antibacterial, vibrant colors

Applications:

premium fashion

shirts

dresses

intimates

Multifunctional, High-Performance:

Natural Antibacterial & Mite-Resistant

Antiviral Activity (HPV16: 96.92%)

Moisture-Wicking

Superior Dyeability

Wrinkle Resistance

Anti-pilling Durability

PEF is derived from renewable biomass feedstocks and delivers intrinsic antilbacterial, antiviral activity (HPV16: 96.92%), UV-resistant and anti-mite performance without chemical additives.

PEF delivers a 43.8% reduction in carbon footprint compared to PET, it’s production also avoids harmful additives, enhancing safety andenvironmental compliance.

Yes. As a sustainable textile material, PEF can be blended or interwoven with natural fibers such as cotton, wool, and lyocell, as well as synthetic fibers like PET and nylon. Blending enhances comfort, functionality, and fabric versatility.

PEF bio-based fibers are positioned for high-growth markets demanding sustainable and functional textile materials. With ongoing R&D, applications in technical textiles, advanced composites, and high-performance fabrics will continue to expand.

PEF fibers can be spun, woven, knitted, or blended to create a wide range of textile and industrial products:

Apparel & fashion textiles

Functional & performance textiles

Home textiles

Industrial yarns & technical fibers

Fiber blends & hybrid yarns

Contact our expert team to request samples, product quotes, technical data, or customized solutions - we will respond within 24 hours.